Running PyDome

- Install Python. The code was developed under Python 2.7. Packages for

all operating systems (Windows/Mac/Linux) are available from http://www.python.org/getit/

- Create a directory under your users home directory and copy all the PyDome files there. This will be where you run the script from and save the output to.

- Update the 'config.py' script to set the dome diameter and the geodesic frequency.

- Run the 'geo.py' script from the command line. The default output is to

print the results on the screen, so to save it to a text file just

redirect the output:

python geo.py > output.txt

An

average desktop PC should take around 45 seconds to run for a 6V

sphere, with lower frequency calculations taking even less time.

|

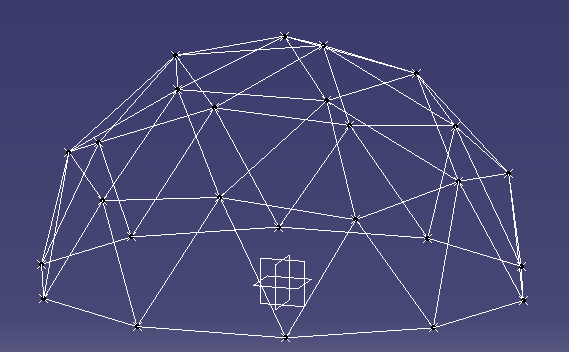

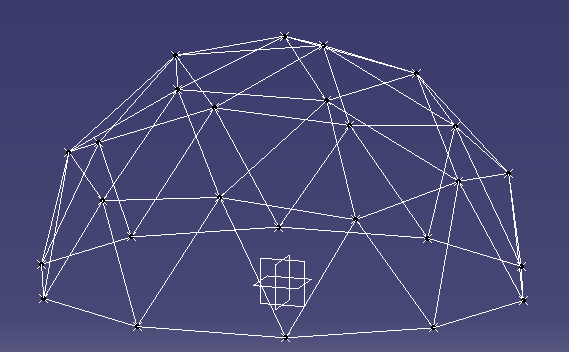

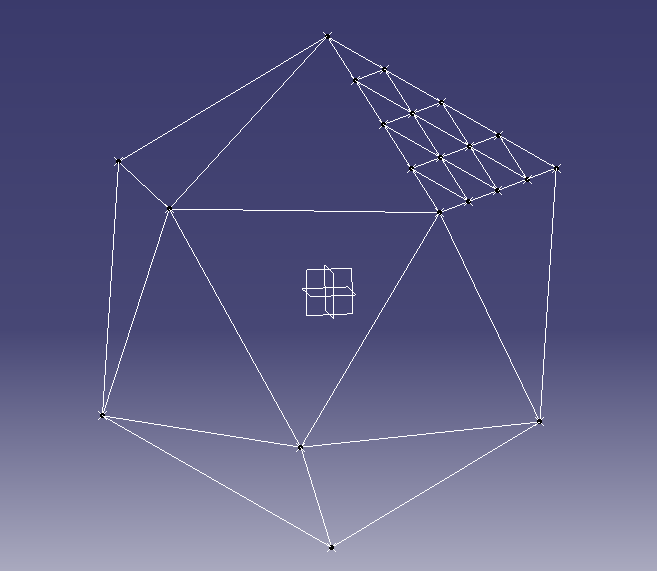

| 2V Dome results in CAD |

Output

The output consists of the list of points with Cartesian coordinates:

/**********************************************************/

* Points *

/**********************************************************/

Pt77 = (-3782.10808464, 129.73646238, 4656.05271517)

Pt246 = (5547.56463791, 1201.67534466, 1944.35155109)

Pt112 = (4854.10196625, 3526.71151375, 0)

Pt402 = (1854.10196625, 4253.25404176, -3804.22606518)

Pt165 = (-571.430583503, -5647.38560167, -1944.35155109)

As well as the list of edges showing both endpoints and their coordinates:

/**********************************************************/

* Edges *

/**********************************************************/

Point Pt77 Edge List:

----------------------------------

Edge187: Pt74 = [ -3000.0, 974.759088699, 5103.90485011] - Pt77 = [ -3782.10808464, 129.73646238, 4656.05271517]

Edge188: Pt77 = [ -3782.10808464, 129.73646238, 4656.05271517] - Pt76 = [ -3917.72834195, 1272.94710279, 4362.45462008]

Edge200: Pt77 = [ -3782.10808464, 129.73646238, 4656.05271517] - Pt75 = [ -2736.75911987, -209.918005711, 5335.36165135]

Edge202: Pt83 = [ -3464.10161514, -1125.55484451, 4767.92683375] - Pt77 = [ -3782.10808464, 129.73646238, 4656.05271517]

Edge203: Pt79 = [ -4618.03398875, 449.02797658, 3804.22606518] - Pt77 = [ -3782.10808464, 129.73646238, 4656.05271517]

Edge204: Pt77 = [ -3782.10808464, 129.73646238, 4656.05271517] - Pt84 = [ -4428.16927497, -759.490479512, 3976.74377899]

Generated code for CAD Programs

It

is easy to modify the code to generate output in a format which can be

easily used in a CAD program. I have used CATIA for my examples, as it

can run Visual Basic macros to do tasks. I simply created a macro which

recorded the creation of two points and a line between them for an edge.

Then I added the function ‘Get_CATIA_Desc’ to the Coordinates and Edges

classes to print out the data with the right text. To generate all the

points and edges in a CATIA part I just copy and paste this output into

the VB editor and run the script.

Sample VB code to create a point in CATIA:

Set hybridShapePointCoord369 = hybridShapeFactory1.AddNewPointCoord(1958.86417097, -636.473551394, -5635.40172286)

body1.InsertHybridShape hybridShapePointCoord369

part1.InWorkObject = hybridShapePointCoord369

part1.Update

Program Structure

The

advantage of using a language like Python is the Object Oriented (OO)

nature of the language, which enables the code to reflect the structure.

The objects which are modelled are the geodesic sphere (GeoSphere.py),

icosahedron faces (IcoFace.py), edges, (Edge.py), and coordinates/points

(Coordinates.py). The main GeoSphere class keeps track of a list of all

the points and edges.

Algorithm

Each

face of the icosahedron has known coordinates, as determined from the

equations in

Platonic Solids Tutorial. Given these

coordinates we can process each of the 20 faces at a time and use vector

maths to calculate the delta vectors from a starting point A to the

other two corners B and C. The location of each of the

intermediate points can then be determined by scaling the delta vectors

according to the frequency, and then iterating to get each row and

column.

|

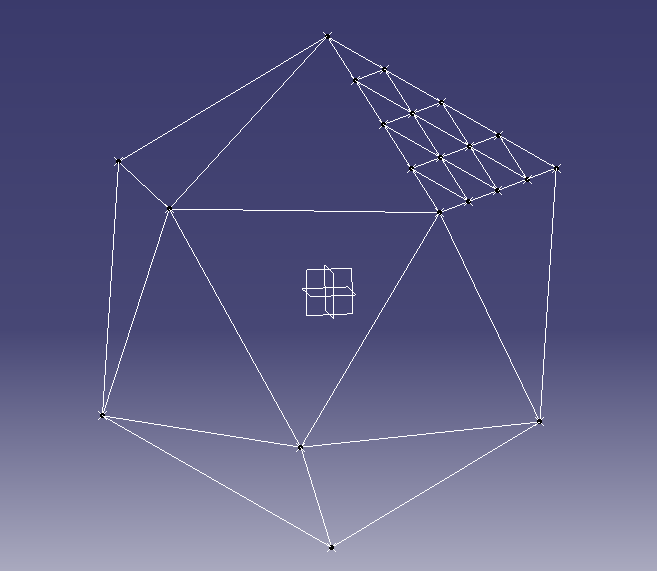

| Icosahedron with one face divided for a 4V geodesic sphere |

For example a frequency 4 dome would have each face divided into

4 rows and 4 columns.

The scaled delta vectors would then be calculated as:

where f is the geodesic frequency.

With

one counter for the row number and one for the column number, we can

start at point A and use a loop over these counters to determine each

point.

for i in range(0,self.freq_n+1): -- Row number

for j in range( 1, self.freq_n - i + 1): -- Column number

# Calculate the new coordinates based on the offset from the initial point (A)

As

each face is added to the GeoDome class the coordinates from each face

are added to the global list. Once all faces have been added then the

list can be checked for duplicate points, as any points on the line

where two faces meet will be doubled up.

The

final step is to project each point onto the sphere. So far all the

calculations have been in Cartesian coordinates (x,y,z), however the

Coordinates class also keeps the polar coordinates (theta, phi, r). Each

point will then have its polar coordinates radius (‘r’) set to the same

value while keeping the angles theta and phi the same. Setting the

radius will also recalculate the Cartesian coordinates for each point.

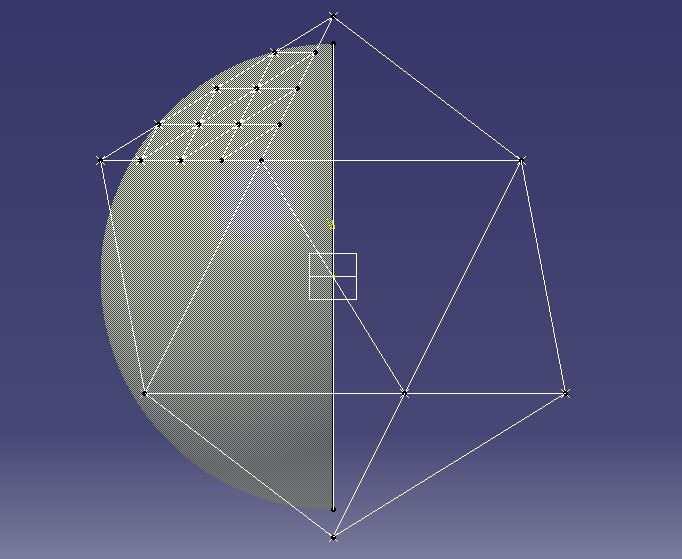

|

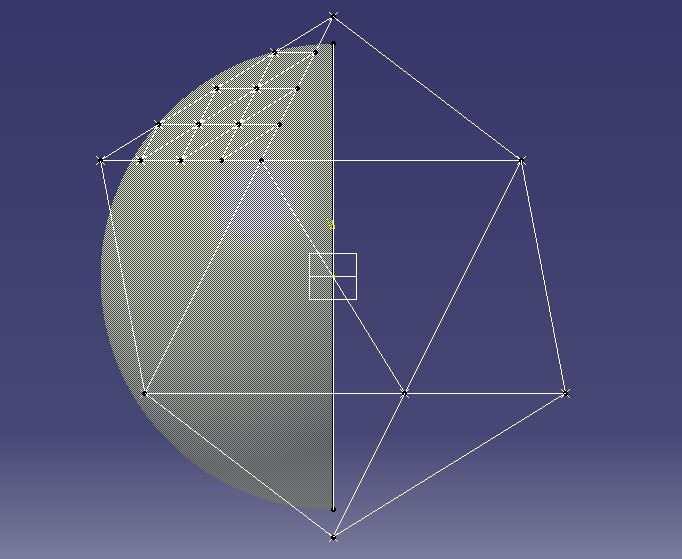

| Icosahedron with sphere for projecting points |

Advanced Modifications

The user parameters are defined in a small section at the beginning of the 'geo.py' script. Currently there are three parameters, the frequency of the geodesic (frequency_n), the radius of the dome (R_mm), and a flag for sphere or dome calculations. The coordinates should be entered in mm as this gives better readability in the final results.

To

calculate the coordinates of a 6 metre (6000mm) radius dome of frequency 6,

set these variables to the corresponding values as shown:

R_mm = 6000

frequency_n = 6

Dome_calc = True

There

are potentially lots of different methods of dividing the faces of the

icosahedron. Traditional geodesic domes or spheres divide each flat face

into equal lengths. When the points are projected onto

the

sphere they then have different lengths. An alternative method is to

divide the arc between the edge vertices into equal angles. In order to

change the calculation method for each face,

modify

the file GeoSphere.py in the function Add_Face. This section of the

code takes the 3 corner vertices and then calculates all the points

within that face. Just replace the function 'Get_Edges_Equal_Distance'

with an equivalent function.

#----------------------------------------------------

# Use this function to divide faces by equal distance

#

edge_list = F1.Get_Edges_Equal_Distance()

To Do List

For each hub point calculate the angle of at which each edge meets at the hub. This would be both the angle between the edges and the angles of the edge from a flat plane.